Independent Research

Junior/senior level experience in sculpture.

Sculpture Works

Mission: (Project Description)

Mission: (Project Description)Hollow lost wax casting method: A unique wax pattern will be developed using plaster and rubber molds. The wax pattern will be taken through the “Lost Wax Process” to create a unique bronze or aluminum sculpture with a patina or alternative finishing method. Individual students have a choice to cast a wax form presented from a previous course or to create a new hollow casting for this project. A hollow lost wax casting method is the only technical criteria. If a new casting is to be produced, you are encouraged to create a composition and concept that pushes the envelope of this level course.

This project will challenge and further introduce the student to the processes of casting metal. A traditional investment material of plaster, silica sand and silica flour will be used for this project. The student should show an understanding of the methods listed below. A metal form will be cast and finished by the student.

Learn the process of developing a metal casting using a two-part sand resin bond mold. The first part of the project will be to create a pattern using a variety of methods and materials. Mixing sand and resins the student will create a mold. The mold will be used to create a void to pour metal. The metal sculpture will then be finished accordingly. The student will be graded by keeping a schedule with the processes of the assignment as well as the finished form. Keep up, so you do not fall behind.

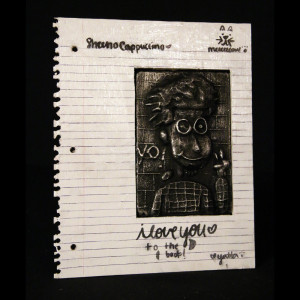

In this project the student will learn the process of developing a “Relief” metal casting using a Scratch Block, a sand block bonded with resin, to create a negative or inverse of a final relief sculpture. Metal will be poured into the scratch block to create the finished form. The metal relief sculpture will be finished, and chased using metal working tools. Then dioxide and wax will be applied to the surface. And finally, a strategy must be developed to display the relief form.

In this project the student will learn the process of developing a “Relief” metal casting using a Scratch Block, a sand block bonded with resin, to create a negative or inverse of a final relief sculpture. Metal will be poured into the scratch block to create the finished form. The metal relief sculpture will be finished, and chased using metal working tools. Then dioxide and wax will be applied to the surface. And finally, a strategy must be developed to display the relief form.